Overpaying for supplies and services? You’re not alone. Companies without centralized purchasing systems often spend 25% more than necessary. But with price benchmarking, you can reduce costs, improve efficiency, and make smarter procurement decisions.

Here’s what you need to know:

- Centralize your vendor data: Use tools like bizSupply to consolidate pricing, contracts, and performance metrics in one place.

- Compare rates to market benchmarks: Analyze industry reports, peer pricing, and tools to identify overpriced vendors.

- Focus on Total Cost of Ownership (TCO): Beyond upfront costs, factor in maintenance, logistics, and quality to uncover hidden expenses.

- Negotiate with data: Use benchmarks to challenge inflated prices and secure better terms.

- Track and re-benchmark regularly: Markets change, so review vendor pricing and performance often to stay competitive.

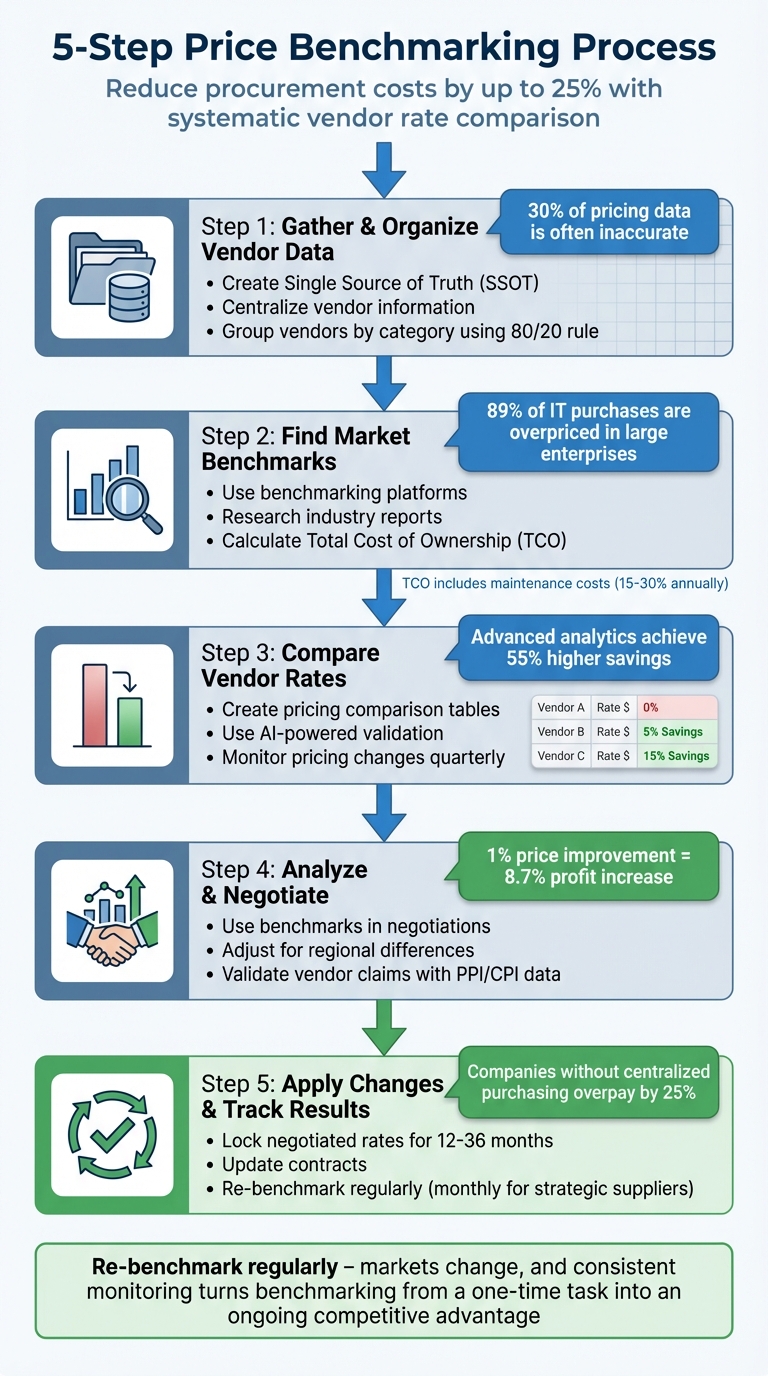

5-Step Price Benchmarking Process for Vendor Rate Comparison

Analyzing and Benchmarking: What It Is, Why It Matters, and How To Do It

Step 1: Gather and Organize Your Vendor Pricing Data

Accurate vendor pricing data is the backbone of any effective negotiation. Without it, you’re essentially navigating blind. In fact, poor data quality can cost organizations a staggering $15 million annually, and when it comes to pricing specifically, 30% of data is often estimated to be inaccurate.

The first step is to establish a Single Source of Truth (SSOT) for all vendor-related information. When every department relies on the same up-to-date vendor profiles, you eliminate confusion and ensure that everyone is working with consistent and reliable pricing information.

Platforms like bizSupply make this process easier by centralizing purchase transactions and integrating seamlessly with your existing systems. The platform doesn’t just track pricing; it also consolidates product catalogs, contract terms, performance metrics, and compliance certifications – all in one place. This automation reduces errors from manual data entry and frees up your team to focus on more strategic decisions rather than getting bogged down in administrative tasks.

Create a Central Repository for Vendor Information

A centralized repository is key to breaking down data silos and ensuring all teams are on the same page. Instead of scattered records across spreadsheets, emails, or ERP modules, everything is unified in one database. This means no more digging through email attachments or outdated files – your procurement team can instantly access current pricing, payment terms, and renewal dates. This level of visibility is especially valuable during audits or when negotiating contract renewals.

Modern tools like bizSupply go a step further by offering audit trails that log every change made to vendor records, ensuring complete transparency. Automated data validation features catch errors early by flagging unlikely price points before they enter the system. By improving data accuracy, organizations can see margin improvements of 2-7%.

With all vendor data in one place, you can also organize it more effectively by category.

Group Vendors by Category

Sorting vendors by service type, category, or spending level turns raw data into actionable insights. Instead of simply listing vendors alphabetically, you can categorize them based on what they provide – like office supplies, IT services, waste management, or credit card processing. This method makes it easier to spot duplicate suppliers and uncover opportunities for consolidation.

Leverage the 80/20 rule to prioritize your efforts. Typically, 80% of your spending is concentrated with just 20% of your suppliers. Start by conducting a 12-month spend analysis, arranging purchases from highest to lowest spend. This helps identify the categories that need immediate attention for benchmarking while keeping the data manageable. For these high-impact categories, you can then create standardized evaluation templates to ensure consistent scoring across vendors and stakeholders.

Step 2: Find Market Benchmarks

Once your vendor data is in order, the next move is figuring out what you should be paying. Without reliable benchmarks, negotiations can quickly become expensive. According to NPI Financial, large enterprises overpay for 89% of their IT purchases due to inconsistent pricing and confusing licensing terms. Even a well-benchmarked 1% price increase can lead to an average 8.7% rise in profit – a small change with a big impact.

Start by using specialized benchmarking platforms that provide SKU-level pricing based on real transaction data. These platforms analyze billions of dollars in purchases, helping you see what similar companies are paying. For broader insights, the American Productivity & Quality Center (APQC) offers "Open Standards Benchmarking" reports across various industries, from aerospace to healthcare. One recent report, based on over $20 billion in procurement data, highlights spending habits and pricing norms.

Economic indicators like the Consumer Price Index (CPI) and Producer Price Index (PPI) can also help you evaluate vendor price increases. Gartner notes that vendors are citing inflation, labor shortages, and supply chain issues to justify renewal price hikes of 10% to 30% in some cases. Comparing these claims against official economic data can help you determine whether the proposed increases are reasonable or inflated.

To set a strong benchmark, dive into external pricing data and industry reports.

Research Industry Reports and Peer Pricing

Industry reports are a treasure trove of data that can give you the confidence to negotiate effectively. Procurement software providers often publish benchmark reports based on their proprietary data, offering valuable insights into category-specific pricing trends. Beyond these formal reports, peer networks can provide qualitative insights that numbers alone can’t capture. Conversations with colleagues in similar industries can uncover hidden risks or opportunities with certain suppliers.

Modern tools are also changing the game. Many platforms now use AI-powered tools to deliver real-time pricing alerts. For example, some tools can instantly generate counteroffers and negotiation strategies based on market floor-price data. This shift from static, yearly reports to real-time benchmarking allows you to track market changes quarterly instead of waiting for an annual update. With 78% of top SaaS companies adopting value-based pricing – where prices are determined by perceived worth rather than internal costs – updating your benchmarks quarterly is essential to stay competitive.

But pricing alone doesn’t tell the whole story. To make informed decisions, you need to look at the bigger picture.

Calculate Total Cost of Ownership (TCO)

Market benchmarks show you standard vendor prices, but a Total Cost of Ownership (TCO) analysis reveals the full financial impact. The upfront price is just the tip of the iceberg. TCO takes into account maintenance, support, delivery, implementation, and internal management costs. A supplier with a lower price tag might actually cost more in the long run if they have a high defect rate or inconsistent delivery, leading to delays and extra work.

When calculating TCO, Gartner suggests asking vendors for detailed cost breakdowns. Look at factors like purchase versus leasing options, pricing tiers, included features, training, shipping and installation, warranty terms, and upgrade schedules. Payment terms also play a role – early payment discounts or net-60/90 arrangements can improve cash flow and add value to the deal. Maintenance and support costs alone can add 15-30% annually to your total cost, so these shouldn’t be overlooked.

To take TCO analysis even further, tools like bizSupply’s waste detection feature can scan your contracts for unused subscriptions or overlapping services. This AI-powered tool identifies inflated pricing and hidden markups, helping you find immediate savings during renewals. By cutting waste and standardizing your data for fair comparisons, you’ll get a clearer picture of true market value – not just the price on paper.

Step 3: Compare Vendor Rates

Now that you’ve organized your vendor data and established market benchmarks, it’s time to compare vendor rates side by side. Using the bizSupply dashboard, you can quickly spot pricing gaps and identify where you’re overspending.

The dashboard leverages AI-powered SKU-level validation to match your current pricing against benchmarks derived from billions of dollars in purchase data. Simply input vendor responses, and the system will calculate price differences for you. High-priced outliers – like a $0.14 quote compared to a $0.06 benchmark – are flagged visually, making it easy to spot savings opportunities.

According to Boston Consulting Group, organizations using advanced analytics in procurement achieve 55% higher savings than those relying on traditional methods. Formal benchmarking programs can lead to 17% higher savings, while companies without centralized purchasing functions often overpay by 25%. These numbers highlight just how much money is at stake – funds that could be redirected to fuel growth.

Create a Pricing Comparison Table

A pricing comparison table is a valuable tool for identifying which contracts need immediate attention. It breaks down vendor names, item descriptions, current rates, benchmark rates, and potential savings. Here’s an example:

| Vendor Name | Item Description | Current Rate (USD) | Benchmark Rate (USD) | Savings Potential (%) |

|---|---|---|---|---|

| ABC Company | Shop Towel (6×6) | $0.16 | $0.06 | 62.5% |

| Johnson Uniforms | Shop Towel (6×6) | $0.10 | $0.06 | 40.0% |

| XYZ Company | Shop Towel (6×6) | $0.06 | $0.06 | 0.0% |

Take ABC Company, for example. Their pricing is 62.5% higher than the benchmark. Even if they offer a "discount" to $0.14, you’re still overpaying. This table helps you focus on the 20% of line items that account for 80% of your spend, allowing you to prioritize the most impactful negotiations.

Once you’ve identified competitive rates, use the dashboard to "lock" those prices for 12 to 36 months. This ensures vendors can’t introduce gradual price increases that chip away at your savings.

Monitor Pricing Changes Over Time

Identifying rate discrepancies is just the beginning – you also need to stay on top of market trends. Prices fluctuate as market conditions change, and what seemed like a great deal six months ago might now be overpriced. Regularly tracking these shifts ensures you’re not caught off guard by "silent price creep", where vendors slowly increase rates across invoices, hoping it goes unnoticed.

The bizSupply dashboard offers real-time benchmarking, enabling you to review market changes quarterly. For instance, you might negotiate a 5% discount and feel satisfied, but if benchmarks reveal a 40% drop in market rates, you’re still overpaying.

Vendors often cite inflation, labor shortages, or supply chain issues to justify renewal hikes of 10%–30% (Gartner). By comparing these claims with actual market data, you can push back on inflated increases. Regular monitoring also helps you identify when switching vendors might make sense, giving you more leverage in negotiations and keeping your costs optimized over time.

sbb-itb-291cea0

Step 4: Analyze Price Differences and Negotiate

Once you’ve compared vendor rates, the next move is to dig into the differences and start negotiating. Break down vendor quotes into components like raw materials, labor, overhead, and margins. This breakdown helps you identify inflated costs and gives you specific points to address during negotiations.

For example, if a vendor claims rising raw material costs, check those claims against reliable sources like the Producer Price Index (PPI). Interestingly, research from the Institute for Supply Management shows that while nearly 60% of procurement leaders prioritize Total Cost of Ownership in their evaluations, fewer than 30% actually have formal models to calculate it. This lack of analysis often leads companies to accept vendor pricing without questioning the details.

Use Benchmarks in Vendor Negotiations

Walking into a negotiation armed with solid data can shift the dynamic entirely. Instead of asking vaguely for "better pricing", show vendors how their rates compare to market benchmarks. Laying out vendor quotes alongside industry averages highlights any pricing gaps.

By presenting cost estimates tied to production processes and current market trends, you demonstrate a clear understanding of their cost structure. For high-value purchases, you might even request open-book costing, where vendors provide transparency about their key cost components. If they claim high overhead, use your benchmark data to challenge those numbers. Automated tools can also help flag contracts that need closer scrutiny.

From there, refine your approach by factoring in regional pricing differences.

Adjust for Regional Price Differences

After using benchmarks to guide your negotiations, take regional factors into account for a more accurate cost comparison. Not all price differences are unjustified – some stem from legitimate regional variations. For instance, labor costs might be lower in rural areas compared to major cities, while transportation costs could rise with greater distances from distribution hubs. Adjusting for these factors ensures you’re making fair comparisons.

Break down the Total Cost of Ownership to include logistics, fuel surcharges, and any location-specific fees. A vendor with slightly higher unit prices but lower shipping costs could ultimately offer better value than a distant supplier with cheaper rates. Similarly, a local supplier might charge more per unit but save you money through faster delivery and reduced inventory costs.

When vendors propose price increases of 10%–30% – which is fairly common in today’s market – validate those hikes against regional economic data like inflation rates and employment cost indices. If you’re weighing a local supplier against a national one, adjust your benchmarks to account for differences in overhead. National suppliers may benefit from economies of scale, but local vendors often provide flexibility and personalized service that can be just as valuable to your business.

Step 5: Apply Changes and Track Results

Once you’ve negotiated better rates, put them into effect right away to start saving. Make sure these updated rates are logged in your centralized system so everyone in your organization has access to the latest pricing and terms. Without proper updates, there’s a risk of unauthorized purchases slipping through.

Secure your negotiated pricing for 12, 24, or 36 months to protect against unexpected price increases and ensure predictable savings. Keep in mind that the invoice price is just one part of the equation – track the full procurement costs, which include logistics, quality-related expenses, and administrative overhead. This gives you a clearer picture of the actual value your vendors provide. Use supplier scorecards to measure key metrics like on-time delivery (aim for 95% or higher) and defect rates (keep these below 1%) to confirm that your vendors are meeting all contract expectations, not just pricing.

Finally, update your contracts to reflect these changes and set up alerts to monitor compliance and performance.

Update Contract Terms with New Rates

After recording the new rates, formalize them in your contracts. Store these updated agreements in your contract repository and track important details like obligations, milestones, and expiration dates. This way, you’ll have plenty of time to re-evaluate or renegotiate terms before renewals. Involve key stakeholders – such as technical experts, finance teams, and business partners – when implementing these changes. Their input ensures that cost models are accurate and quality standards are upheld. Collaboration at this stage helps identify potential issues early and ensures everyone is aligned with the new terms.

To stay ahead, set up automated alerts in bizSupply to track contract expiration dates and renewal timelines. These alerts work alongside your real-time pricing data, ensuring that all teams are operating with the most current information. They also prevent last-minute rushes by giving you ample time to renegotiate or re-benchmark. Additionally, automated spend analysis can flag instances where negotiated rates aren’t being applied consistently, allowing you to address discrepancies quickly.

Re-Benchmark on a Regular Schedule

Markets are constantly changing – costs fluctuate, and vendor performance can vary over time. Regular re-benchmarking helps you stay competitive and identify fresh opportunities to save.

Organize your vendors into tiers to determine how often they should be reviewed. For strategic suppliers, conduct reviews monthly. Preferred vendors can be reviewed semi-annually, while transactional vendors typically only need attention when issues arise. This tiered approach ensures you focus your efforts on the 20% of suppliers that usually account for 80% of your total spend.

Keep an eye on indices like the Consumer Price Index (CPI) or Producer Price Index (PPI) to validate future price changes from vendors. If a supplier claims their costs have increased, you’ll have the data to verify their claims. With bizSupply’s real-time data and automated alerts, this monitoring becomes seamless, turning benchmarking into an ongoing process that keeps your procurement strategy sharp and competitive at all times.

Conclusion

Price benchmarking isn’t a one-and-done task – it’s an ongoing effort that sharpens your procurement strategy and helps keep costs in check. By centralizing vendor data and leveraging industry benchmarks, you can uncover opportunities to save money and improve efficiency.

The real game-changer lies in consistent monitoring. For example, companies that embrace benchmark pricing often see a 1% improvement in pricing translate to an average 8.7% increase in operating profit. On the flip side, businesses without centralized purchasing systems tend to overpay by around 25%. These numbers highlight the importance of re-benchmarking regularly. Markets fluctuate, vendor performance changes, and fresh opportunities are always on the horizon.

Tools like automated workflows, real-time alerts, and centralized dashboards take price benchmarking to the next level. They turn it from a static process into a dynamic, always-on strategy. With these tools, your team can access and act on vendor insights faster, making benchmarking a powerful competitive advantage.

FAQs

How can I keep my vendor data accurate and up-to-date for better price benchmarking?

Accurate, up-to-date vendor data is the backbone of effective price benchmarking. To get started, organize all supplier information – like price lists, contracts, and performance metrics – into a centralized, searchable system. A cloud-based procurement tool works well for this, eliminating the need to juggle scattered spreadsheets or outdated methods.

Keep your database current by scheduling automated imports from vendor catalogs or EDI feeds. Supplement this with occasional manual checks against public price lists and your past purchase records. Regular audits – whether quarterly or timed around contract renewals – are essential for spotting outdated entries, duplicates, or pricing errors that could throw off your benchmarks.

For even greater accuracy, set up data validation rules and cross-check vendor submissions using tools like market surveys or catalog comparisons. Make it a habit to request updated pricing from suppliers and confirm any changes in terms. Staying on top of these updates ensures your records align with the latest market trends, empowering you to make smarter purchasing decisions.

What should I consider when determining the Total Cost of Ownership (TCO)?

When evaluating the Total Cost of Ownership (TCO) for a vendor solution, it’s crucial to account for more than just the upfront price. A complete assessment includes all costs you’ll encounter throughout the solution’s lifecycle. Start with the initial costs, which typically include the purchase price, licensing fees, and any installation or setup expenses. These are the most obvious expenses but only part of the equation.

Next, factor in ongoing costs such as maintenance, support services, software updates, training, and integration work. These recurring charges can add up over time and should be part of your calculations.

Don’t forget about indirect costs that might not be immediately apparent. These can include energy consumption, facility overhead, insurance, taxes, and financing charges. These hidden expenses can significantly influence your budget.

Lastly, consider future expenses. This includes costs for upgrades, potential downtime, scalability requirements, and end-of-life costs like disposal or decommissioning fees. By taking all these factors into account, you’ll have a much clearer understanding of the total investment involved, helping you make smarter decisions when comparing vendor options.

How often should I review and compare vendor rates to stay competitive?

To keep your business competitive and ensure you’re getting the most for your money, it’s smart to review vendor rates at least once a year. Depending on your industry, market trends, or specific contract terms, you might need to adjust this frequency. For industries where costs shift quickly, a review every six months could be more effective.

By regularly comparing rates and terms, you can uncover opportunities to cut costs, negotiate better agreements, and confirm that your spending aligns with current market conditions. Taking a proactive approach to these reviews not only helps control expenses but also keeps your business ahead in a competitive landscape.